Porcelain Production in Historic Factory Buildings

Do you know how “White Gold” is made from inconspicuous kaolinite rocks? Have you ever stood between rumbling, giant-sized ball mills or in front of a running steam engine that once generated power for an entire factory?

These things may arouse feelings of nostalgia among engineering enthusiasts today, but at one time they contributed to the harshest of conditions for factory workers. Porzellanikon is a museum of labour and social history, a museum of technology, a museum of porcelain production. The museum and its exhibits show you everything about porcelain then and now – from porcelain body preparation and plaster mould-making, to whiteware production and decoration. It’s like going on a factory tour in which both man and machine are the focus. Hourly demonstrations in the body mill, slip casting shop and turning shop show how porcelain was typically made over a century ago.

Real-life impressions

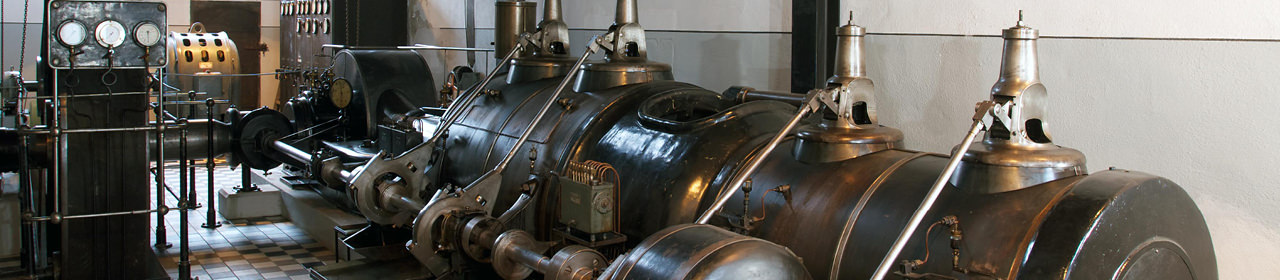

A special area is dedicated to showing you in greater detail what the real Working Conditions of Porcelain Makers were like then and how they are now in Europe. Our aim is to create real-life demonstrations of the production steps using the original machinery that was once installed at various factories throughout Europe. In addition to workstations and production systems, the presentation features the entire power generation complex: Two Steam Engines with a transformer station, a boiler house with its own well, and the tools needed for operation are all on display and fully operational. The steam engine is operated daily.

Share Porzellanikon with Friends